ALLWATER TECHNOLOGIES

Risk Assessments and Audits

Consulting Services

Interface Management Solutions

All Water Technologies Specialist Division

Allwater Technologies (AWT) is a specialist division of IMC focussing on, but not restricted to Corrosion Management Solutions.

Engaging AWT’s consultancies brings more than 100 years of combined “hands on” water treatment industry experience that uses the combined knowledge of our microbiologists, chemists, engineers, and metallurgists’ in a consolidated team of professionals working on your behalf.

AllWater Technologies’ technical expertise and proficiency has, since 1992, been perfected through our local, national, and international working with major property/building owners, and managers, and the constantly improving knowledge of our team.

Experience, knowledge and longevity in the industry make our team at AllWater Technologies your perfect partner to investigate, manage and provide solutions on all types of corrosion problems from condenser water pipe systems, valves, fire safety systems, to ensuring that you have the correct chemical treatment suppliers among a range of other services.

Proudly offering our clients interface management solutions for a better approach that assist building owners and managers achieve the highest standards of preventative maintenance.

Risk Management Plans and Audits

- National and International Coverage (AUSTRALIA-MALAYSIA-THAILAND-ASIA)

- Beyond Compliance

- Proactive Security

- Australia’s leading Legionella Risk Management Assessors and Auditors

- IMC has the credentials, experience and corporate culture to professionally manage and report all projects decisively.

- Professionalism, resourcefulness and respect underpin our values.

- Registered DHS (Victoria) accredited Auditors

Risk Management Consultants

James Withnall

Risk Management Consultant/DHS Certified Cooling Tower RMP Auditor(208) based in New South Wales.

Ms Yih Pien(Ping) Chang

Risk ManagementConsultant/DHS Certified Cooling Tower RMP Auditor(213) based in Queensland

Consultancies Include:

Consultancies include:

- Corrosion Management Solutions for open and closed loop systems

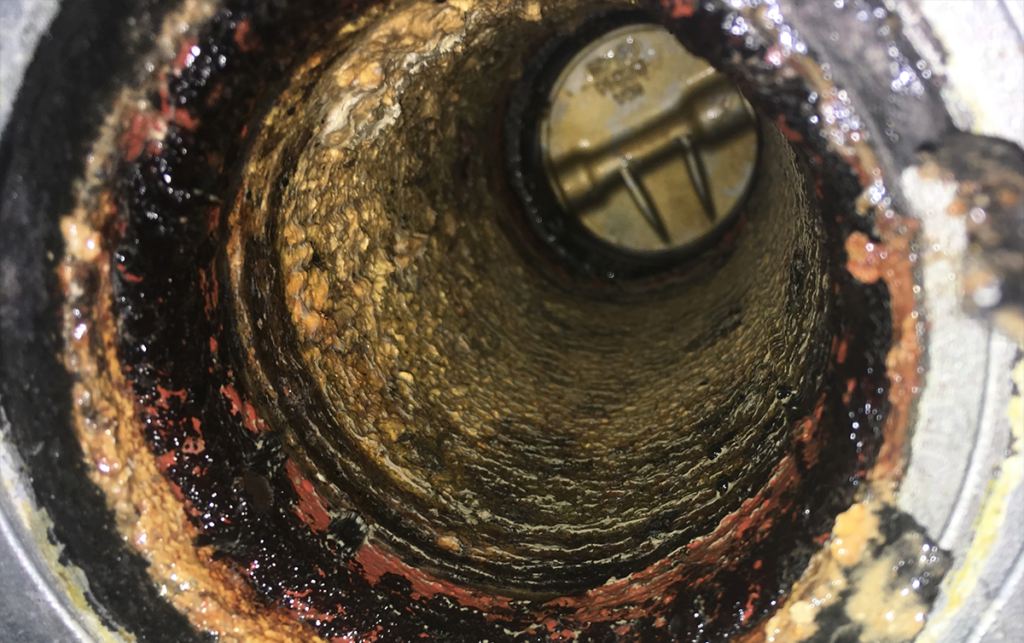

- Corrosion monitoring Programmes (We Measure What You Can’t See)

- System water corrosivity evaluations – analysis of the recirculating water for corrosion product and treatment chemical concentrations plus system control indicators and trends

- Ultrasonic linear velocity pipe flow measurements

- Data logging Corrosion Monitors – instant response measurement of applied changes made to the operation of systems

- Pipe wall thickness measurement

- X-Ray fluorescent Alloy and Deposit Composition verification – on site

- 3D Laser Microscope Corrosion Coupon Analysis and Pit Depth measurement

- Water analysis, identification of impurities and evaluations

Pipe wall thickness measurement

Measurement of condenser water pipes, fire sprinklers, water storage tanks, chiller tubes & chiller header box walls and baffles.

Engineering assessments for the longevity of condenser water system components.

Boiler preheat and condensate systems NDT(non-destructive testing) pipe wall thickness assessments

X-Ray Fluorescent (XRF) identification of alloy base metal composition and international coding.

Assessment of internal metallic protective coatings (galvanizing) especially of chiller isolation valves of mixed metallurgy. Identification of major metallic components of corrosion deposits and other accumulations such as strainer basket contents.

3D images from any rotational angle provides valuable information at annual inspection times and completes engineering reporting by providing quantitative data.

Forensic inspection of corrosion coupon surfaces allows accurate measurement of pit depths and therefore longevity evaluations of critical system components.

Ultrasonic transducer measurements of water linear velocity within corrosion coupons racks ensures the coupons are exposed to the condenser water environment conforming to the applicable standards. Without this basic compliance corrosion results may be unreliable and of little real value.

Deposit Observation Programmes

INTERFACE MANAGEMENT

Interface Management involves IMC either managing or advising on the various water treatment, biological and corrosion management of all water systems on a property in order to achieve maximum performance. As the appointed party, IMC will oversee all water treatment operations to ensure that the systems are operating effectively and in accordance with current legislations & standards.

IMC’s team of microbiologists, engineers, chemists, metallurgists, and technicians have more than 100 years of “hands on” water treatment experience from operating as service technicians to national and international senior management. Through our program we will always act in the best interests of the client to ensure the highest quality water treatment program is in operation, delivering the best possible results. Regular meetings, reports and feedback occurs between all parties to ensure a harmonious and effective result.

BENEFITS OF PARTNERING WITH ALLWATER TECHNOLOGIES (INDEPENDENT MONITORING CONSULTANTS)

Independent Monitoring Consultants are industry recognised professionals in the field of Water Management, Microbiology, Corrosion Monitoring and Air Quality. IMC has an unmatched depth of technical knowledge and experience in the water treatment industry making us the perfect fit to manage this critical service on your behalf.

IMC have more than 100 years of combined hands-on experience in the industry with many of our staff having been engaged in the water treatment industry prior to joining IMC as technicians all the way up to management in Australia and overseas.

Our team consists of Metallurgists, Chemists, Microbiologists, Engineers, and Project Managers.

IMC has its own NATA accredited microbiological laboratory and a dedicated corrosion laboratory operating in compliance with ASTM and Australian Standards.

IMC performs independent corrosion, chemical, and microbiological analysis.

IMC provides a comprehensive tender document, which includes strict KPI’s.

IMC does not give preferential treatment and invites all water treatment companies to tender on the preventative maintenance of your expensive assets choosing the successful tender in partnership with the client based on value for money, performance, and experience.

IMC performs its own costing of works against the submitted tenders, a valuable tool to ensure you are paying the correct dollar figure for the services supplied.

Using the extensive experience of our team we will thoroughly examine all tenders and liaise with our clients throughout the decision making process.

IMC will perform regular random checks on the water treatment service provider to confirm their results and to ensure they are providing the highest level of service. Our monitoring procedures will help to ensure that the system operates at optimal levels and will contribute to the operational life of the chillers and associated HVAC equipment. A monthly summary report for all services will be issued.

IMC managing the water treatment contract makes good sense so that you can concentrate on the other areas of your property and its tenants. We will facilitate the entire process.

Cooling tower water treatment is a crucial service in regard to public health and its impact on the community. It is vital in maintaining the systems health both mechanically and biologically. IMC will manage this service to minimise the risk of exposure and to help maintain the integrity of our clients and their business partners.

IMC is backed with significant experience in the various fields encompassing water treatment. IMC will act in the building owners and managers best interests to ensure the highest quality water treatment program is in operation, delivering the best possible results.

Regular meetings and feedback between all parties will form part of this program.

Contact Allwater Technologies

Manager Senior Corrosion Engineer: Alan Hall – B.Tech (Chem), Assoc. Dip. Metalurgy, Cert. Met. Tech

Mobile: 0411 109 353

Email: alan.hall@imc1.net